Understanding the Crucial Importance of Electrical Insulation Tape for Electrical Safety

Electrical insulation tape plays a critical role in safeguarding and insulating various forms of electrical wires and cables. Often referred to as insulating tape, this essential tool is indispensable for ensuring safety in both commercial and residential environments. By effectively preventing electrical shorts and providing defense against moisture, dust, and physical wear, this tape is vital for the durability and reliability of electrical systems. Acknowledging its importance can help you avoid potential hazards while promoting a well-organized and efficient workspace.

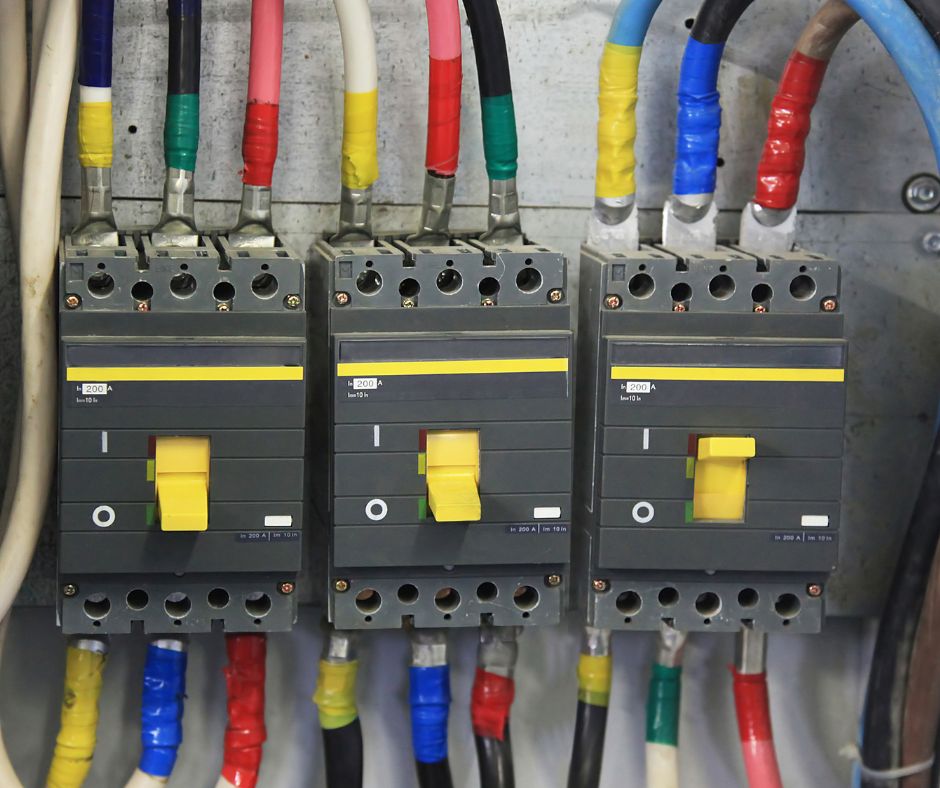

Electrical insulation tape is available in a wide array of sizes, lengths, and colors, with each type specifically tailored for different applications. These diverse choices not only enhance the effectiveness of insulation but also facilitate easier identification and organization of wires through a color-coding system. By utilizing various colors, you can streamline your electrical tasks, enabling quick recognition of specific wires, thereby increasing both your productivity and organizational efficiency.

Analyzing Conditions That Lead to Electrical Tape Melting

Indeed, electrical tape can melt under certain circumstances. This article aims to provide a thorough examination of the temperature thresholds associated with electrical tape, discuss the conditions that may result in melting, and highlight essential overheating indicators to monitor. Understanding these factors is crucial for ensuring the safe and effective application of electrical insulation tape across various scenarios.

Understanding the Safe Temperature Limits of Electrical Tape

Like numerous materials, electrical tape possesses defined temperature limits that must be respected to guarantee safe operation. Most standard electrical tapes can withstand temperatures of up to about 80°C, whereas some heavy-duty versions are designed to endure slightly higher temperatures. When the surrounding conditions surpass these established limits, the structural integrity of the tape may begin to wane, leading to potential failure.

As temperatures rise and approach their maximum threshold, the functionality of electrical tape may start to decline. This deterioration can present itself in various forms, including melting, a sticky consistency, or, in severe cases, complete breakdown. Being aware of these temperature limitations is vital for maintaining safety and efficiency in electrical tasks, ensuring that your projects are carried out without unnecessary risks.

For tasks in extreme environments, it is advisable to consider using high-temperature variants of electrical tape. For instance, heat-resistant tape, formulated from materials such as fiberglass or silicone, can endure temperatures of up to 200°C or even higher, making it an excellent choice for applications exposed to intense heat.

Also Read: Keep Your Pets Safe Around Electricity

Get Your Quote Now!

Ask About Our FREE Electrical Inspections

Identifying Key Factors That Contribute to Electrical Tape Melting

Electrical tape may melt due to various factors, with exposure to extreme heat being the primary concern. Understanding these causes is essential for ensuring the safe and effective use of tape. Below are some of the most common reasons that lead to melting:

Examining the Effects of Heat Exposure on Electrical Tape

The primary cause of electrical tape melting is its exposure to elevated temperatures. If the tape is positioned near hot surfaces, engines, or any components that generate heat, it may begin to soften, bubble, or even melt entirely. Moreover, electrical systems, particularly power circuits, can generate more heat than the tape is rated to tolerate, especially during malfunctions or overload situations.

Thus, when applying electrical tape in areas susceptible to high temperatures, it is prudent to carefully check the temperature ratings of the tape to prevent possible failures and ensure safety.

Evaluating How Environmental Conditions Affect the Longevity of Electrical Tape

Electrical tape is not designed for indefinite durability. Over time, both the adhesive and the tape material can deteriorate, especially when exposed to UV light, moisture, or other harsh environmental factors. This degradation significantly reduces the insulating effectiveness of the tape. As the tape ages, it may become less effective, making it increasingly vulnerable to melting even at lower temperatures than it would typically withstand.

Regular wear and tear are natural aspects of electrical tape’s lifecycle. Therefore, it is essential to routinely inspect the tape for signs of aging or damage to maintain ongoing safety and performance.

Understanding the Risks of Improper Application of Electrical Tape

Using electrical tape under less-than-ideal conditions can lead to premature material failure. For example, if the tape is wrapped too tightly, subjected to friction or heat, or overstretched during application, its overall performance may be compromised. Furthermore, wrapping the tape around sharp edges or applying it to components that tend to overheat, such as light bulbs or electrical outlets, can lead to complications unless the tape is specifically rated for those uses.

Also Read: 10 Ways to Save On Power And Energy Costs

Recognizing Key Signs of Overheating Electrical Tape

If you suspect that your electrical tape is experiencing overheating, several critical indicators warrant your attention. Here are the most common signs that your tape may be melting or suffering from excessive heat:

Detecting a Sticky or Tacky Texture as a Warning Sign of Overheated Tape

A noticeable change in texture, particularly a sticky or tacky feel, is often one of the first signs of melting electrical tape. This alteration can serve as an early warning signal of further degradation, suggesting that the tape may no longer provide adequate insulation for electrical applications.

Identifying Discoloration as Evidence of Heat Damage

Overheated electrical tape may exhibit significant discoloration. You might observe a shift from its standard black or colored appearance to shades of brown, dark gray, or even black. This change occurs as heat causes the tape’s PVC or other materials to degrade. Prompt identification of this issue can prevent further damage to your wires; if ignored, it can lead to melting or even create fire hazards.

Noticing Bubbling or Distortion as Indicators of Excessive Heat

If electrical tape begins to bubble, distort, or warp, it indicates that heat is adversely affecting its structure. This typically occurs when heat causes the adhesive or plastic layers to separate or degrade. The surface may appear uneven or wavy, signaling that temperatures have surpassed safe levels. Upon noticing these bubbles, it is advisable to consult your electrician for a thorough evaluation.

Recognizing a Burning Smell as a Critical Warning Signal

A burning odor near electrical tape is a serious warning sign that should not be disregarded. This smell may resemble melting plastic or burning rubber. When excessive heat causes the adhesive to break down, the resulting fumes can be alarming. Do not overlook this warning. If you detect a burning smell, it may indicate that the tape is on the verge of melting or even igniting.

Visible Smoke as a Major Alarm Signal

If you observe smoke emanating from the electrical tape, it clearly indicates that the heat levels have far exceeded what the tape can tolerate. Smoke is a strong indicator that the tape has likely started to melt or could even be igniting. At this critical moment, it is essential to turn off the power source immediately and contact your electrician for assistance.

Remember – Never use water to extinguish an electrical fire. Always utilize a CO2 fire extinguisher for safety.

Step-by-Step Actions to Take if Electrical Tape Melts: A Safety Guide

If your electrical tape melts, the first step is to disconnect any power sources or turn off any equipment to ensure your safety.

Prioritizing safety is paramount, as electrical hazards can pose significant risks to both life and property.

After confirming that the area is secure, it is advisable to consult your electrician for professional guidance. If a qualified technician installed the tape, they may need to inspect the site for any underlying electrical issues that could have contributed to the problem, ensuring comprehensive safety and functionality for your electrical systems.

Investigating Alternatives to Electrical Tape for High-Temperature Applications

If you frequently operate in environments where temperatures exceed the limits of standard electrical tape, it is wise to discuss appropriate alternatives with your electrician. Here are several options that deserve consideration:

- Heat-resistant silicone tape: This type of tape is specifically engineered to withstand high temperatures, making it ideal for applications where heat is a significant concern.

- Fiberglass tape: A durable option that can handle extreme temperatures without compromising performance or safety.

- Mica or ceramic insulation: For the utmost level of heat protection, specialized insulation materials like mica or ceramic are excellent choices.

Essential Insights on the Hazards Linked to Melting Electrical Tape

In summary, electrical tape can indeed melt, primarily due to excessive heat exposure. Understanding the temperature limitations of your tape and ensuring you select the appropriate type for your specific applications are essential steps in preventing potential issues.

By remaining vigilant for signs such as discoloration, stickiness, or unusual smells, you can take prompt action to mitigate risks. Always prioritize safety and do not hesitate to consult your local electrician for expert guidance when necessary.

Get Your Quote Now!

Ask About Our FREE Electrical Inspections

The Article: Does Electrical Tape Melt? Here’s What You Need to Know first appeared on https://writebuff.com

The Article Electrical Tape Melting: Essential Facts You Should Know Was Found On https://limitsofstrategy.com

This discussion on electrical insulation tape resonates with me, especially when we consider the broader theme of safety in our daily environments. I recall a project I was involved in where we revamped the wiring in an older building. One of the simplest yet most pivotal steps we took was ensuring all exposed wires were properly insulated. The peace of mind that came from knowing we had minimized the risk of short circuits was invaluable.

It’s interesting to hear about your experience with the wiring project. Insulating exposed wires truly plays a crucial role in enhancing safety and preventing accidents. It’s often those straightforward tasks that lay the foundation for a secure environment, and your story highlights how essential it is to prioritize even the smallest details.